Our hour with Veena Sahajwalla: Embracing the Circular Economy

Reduce – Reuse – Recycle – Reform

The queen of recycling materials was our guest in February. Veena Sahajwalla graced us with her generous and lively presence and painted pictures of what is possible in the realm of using waste as a resource. From local modular factories to rural and community micro facilities….

We learned we can all be part of the solution, right across the world, by being more discriminating consumers and waste caretakers, and by supporting localised manufacturing from particular wastes. These small-scale local operations are becoming part of the supply chain of making high quality, durable items.

Veena spoke of being inspired, in her early years, by the Kabadiwala manual waste collectors and transformers, in the streets of the industrial heartland of Mumbai…. making, moving, servicing, manufacturing. “They are the waste warriors,”, she says, “using the most basic technology of tongs and bags, doing backbreaking work in difficult circumstances, like at rubbish tips.

Veena says these people need to be given recognition and far better working conditions. “They bring materials back to life and have a system of collection that is very detailed…they know exactly what they are looking for, they are entrepreneurial; they have connections and make a livelihood by putting materials back into manufacture.”

There are five key points involved in this form of circular economy:

- waste materials valued as a resource

- a variety of jobs

- a network of workers

- entrepreneurial spirit

- collaboration with other elements of the supply chain.

This inspired Veena in the direction of what is now happening at a research centre she set up at UNSW called SMaRT@UNSW Sustainable Materials Research and Technology.

Here’s an extract of some of the work they have pioneered.

THE SCIENCE – MATERIALS Modular Micro factories

Complex packaging materials are rich in important re-usable substances, like aluminum in shiny chip packets or bubble pack medication packs. These are difficult materials to ‘extract’.

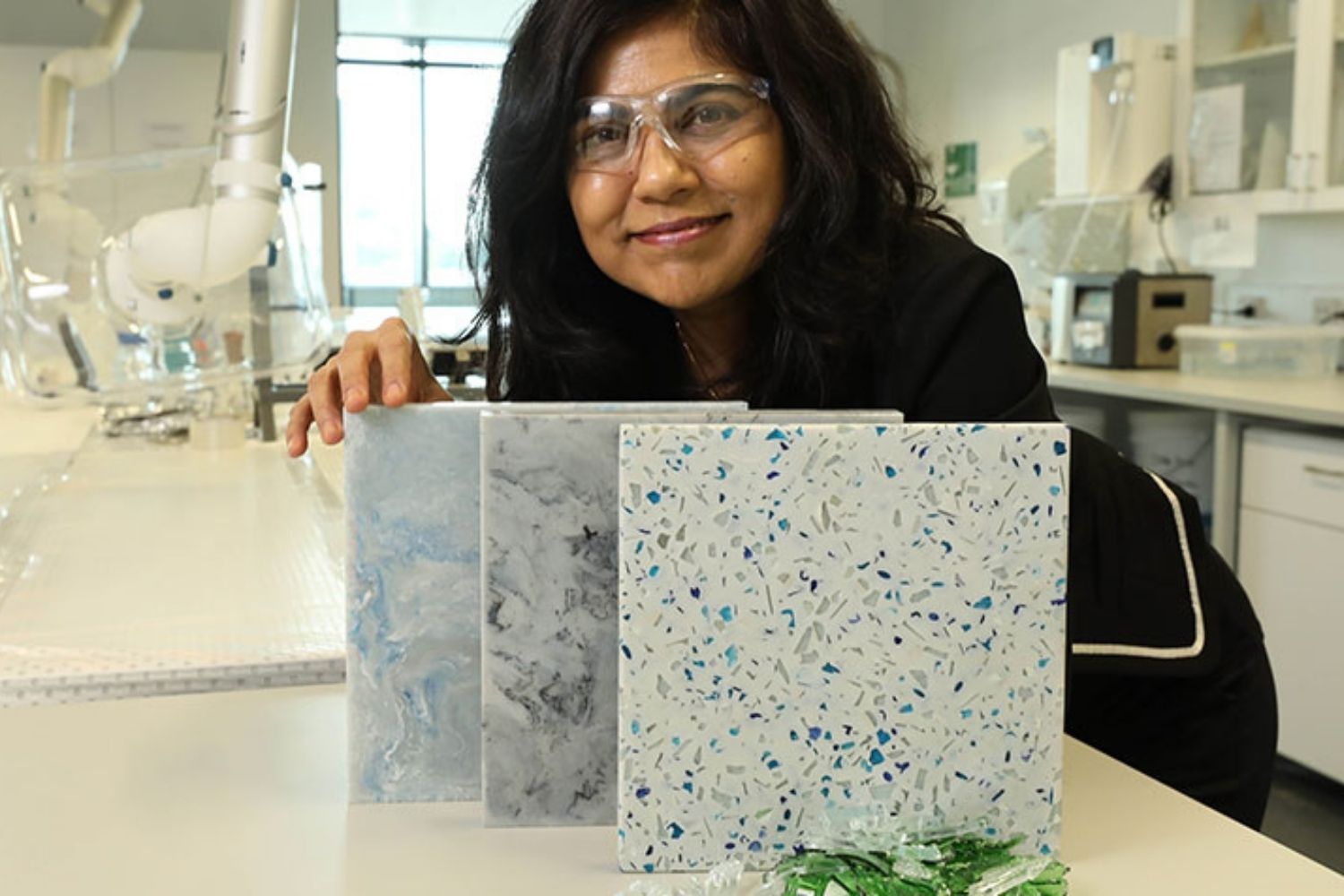

SMaRT has developed technologies that use various, discreet modules to transform problematic waste materials, such as glass, textiles (these give colour) and plastics, into new value-added materials and products, such as engineered green ceramics, furniture, bench tops for the built environment, and plastic filament as a ‘renewable resource’ for 3D printing.

Modular Micro factories are a global phenomenon, are low-cost and can be scaled up, responsive to local supplies, needs and employment. This is fit-for-purpose-recycling, involving, local processes and adding value in the community. They are adaptive and scalable. They can be part of a supply chain, by collaborating with others who make the finished product. The purpose of this type of manufacture is looking after the environment and people.

The first microfactory was set up in Cootamundra in 2021, making tiles.

Highly engineered, value-added products are made, and are in demand not only for their quality and aesthetic appeal but because of the sustainability values.

Green Manufacturing uses feedstock of many types of waste: e-waste in hand devices, hard-drives batteries, metal alloys in nespresso coffee pods and windscreens, the hard plastic in printers

In this way, no matter where you live in the world, all kinds of beautiful products can be made by transforming waste materials. This is all about the alignment of recycling and manufacturing, known as the circular economy.

RESEARCH – then commercialisation

Research brings conceptual and technical innovation; later, commercialisation of the technology can only happen after rigorous fundamentals are in place, and collaboration with manufacturers is established.

The research at UNSW is helping to establish world- leading industries wanting to work with waste and show leadership

Molycorp is commercialised Green Steel Manufacturer Newcastle, converting industrial waste, tyres, polymers, textiles, metal alloys, packaging, e-waste, printers, hard-drives mattresses, e-waste, into steel.

Carbon emissions are closely considered around all innovations.

Veena’s aim is to inspire businesses, Councils and communities to value materials instead of wasting them; to see ‘waste’ as a resource to be retrieved and treasured, not a burden to be flung off.